Parameter

|

Printing color |

4/6/8/10 color |

|

Max .Machine Speed |

500m/min |

|

Max. Printing Speed |

450m/min |

|

Max. Web Width |

1300mm |

|

Max.Printing Width |

1270mm |

|

Printing Length (Stepless Difference Adjustment) |

370~1200mm |

|

Thickness Of Printing Plate |

2.54mm |

|

Maximum Unwinding Diameter |

Φ1500mm |

|

Maximum Rewinding Diameter |

Φ1500mm |

|

Unwind&Rewind Card loading form |

surface friction type Turret double station winding & unwinding,Equipped with servo motor |

|

Paper core in Unwind &Rewind |

3" |

|

Register error |

≤±0.1mm |

|

Tension Range |

100~1500N |

|

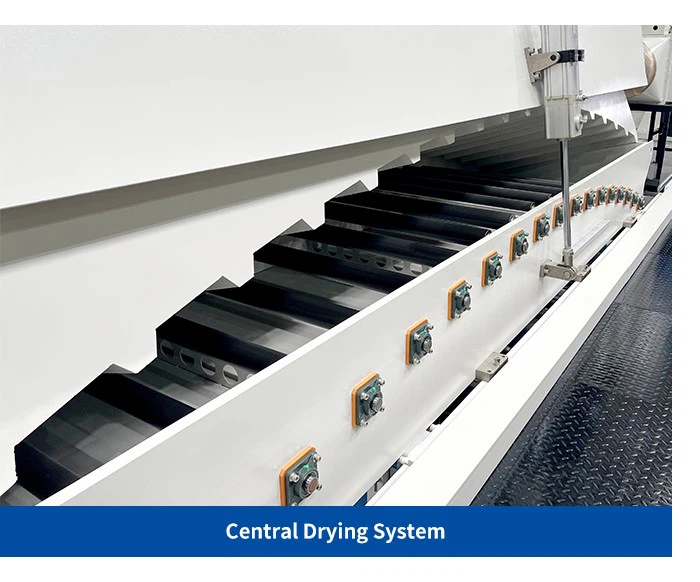

Oven Maximum Temperature |

Max.80℃(Room Temperature 20 ℃) |

|

Speed Of Nozzle From Drying Between Colors |

15~45m/s |

|

Speed Of Nozzle From Central Drying |

5~30m/s |

|

Heating mode |

Electric heating |

|

Machine size |

About L*W*H=15M * 5.5M* 5.5M |

Machine Features

1. Gearless CI flexo printing press to shorten the printing preparation time and save printing consumables.

2. wide web flexo press is easy to operate and improve printing efficiency and quality of printed products.

3. User Interface Humanization

4. Control the servo motor for rewinding and unwinding and feeding and discharging paper to keep constant tension in the printing room.

5. High precision: Full servo CI flexo presses utilize advanced servo motor technology to provide high precision printing and precise control of printing processes.

6. High speed: These presses can operate at high speeds of up to 500 meters per minute, ensuring faster turnaround times and increased productivity.

7.Intelligent control system: Full servo CI flexo presses come equipped with a user-friendly control system that enables operators to easily set and adjust printing parameters.

8.UV curing system: UV curing systems are integrated into full servo CI flexo presses to ensure fast and effective curing of inks, resulting in high-quality prints.

9.Energy efficiency: CI flexo presses feature an energy-efficient design, which reduces power consumption and operating costs, making them an environmentally friendly option.