stack type flexo printing machine is versatile and can be used to print on a variety of materials, including plastic film, paper, non-woven fabric, etc. uses a flexible printing plate, which allows for sharper and more accurate printing. This machine is very suitable in Print on high-volume products such as flexible packaging or plastic labels.

|

TECHNICAL SPECIFICATIONS |

||||

|

Model |

CH8-600H |

CH8-800H |

CH8-1000H |

CH8-1200H |

|

Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

|

Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

|

Max. Machine Speed |

150m/min |

|||

|

Printing Speed |

100m/min |

|||

|

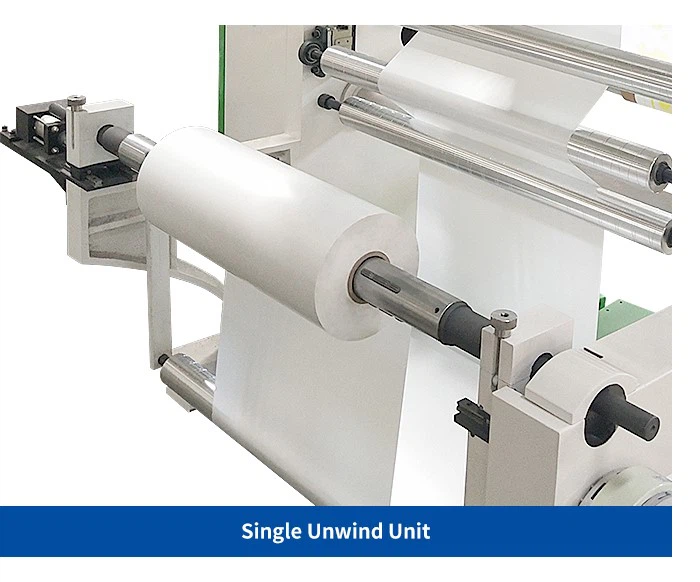

Max. Unwind/Rewind Dia. |

φ800mm |

|||

|

Drive Type |

Gear drive |

|||

|

Plate thickness |

Photopolymer plate 1.7mm or 1.14mm (or to be specified) |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing length (repeat) |

270mm-900mm |

|||

|

Range Of Substrates |

LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon, PAPER, NONWOVEN |

|||

|

Electrical supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

Features

1. When the bopp film flexo printing machine is printing, its path can be changed, its printing can print the front and back at the same time, and its printing color number is very convenient to change.

2. The printed parts are very good and convenient for our operation, like our adjustment, replacement and cleaning are relatively convenient.

3. The printing unit can be separated and meshed independently, and it can also perform 360 registration, which will facilitate the printing of other printing units.

4. It has a wide range of applications and can print various publications