The Flexo printing machine has now been fully automated, and the efficiency of the automatic flexo printing machine is the highest of all printing machines. After development, several different products have been derived from flexographic printing machines. They are Stack type flexo printing machine, Ci flexo printing machine and Inline flexo printing machine.

Parameter

|

TECHNICAL SPECIFICATIONS |

||||

|

Model |

CH4-600H |

CH4-800H |

CH4-1000H |

CH4-1200H |

|

Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

|

Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

|

Max. Machine Speed |

120m/min |

|||

|

Printing Speed |

100m/min |

|||

|

Max. Unwind/Rewind Dia. |

φ800mm |

|||

|

Drive Type |

Gear drive |

|||

|

Plate thickness |

Photopolymer plate 1.7mm or 1.14mm (or to be specified) |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing length (repeat) |

300mm-1000mm |

|||

|

Range Of Substrates |

LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon, PAPER, NONWOVEN |

|||

|

Electrical supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

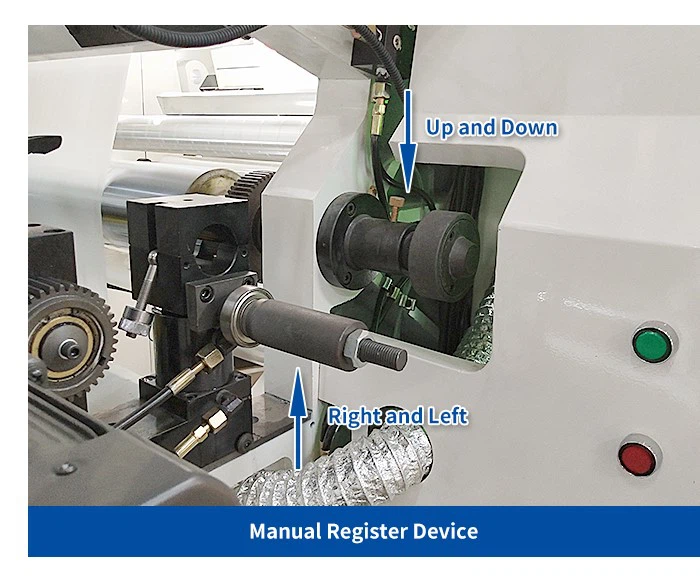

Detail Image

Non woven bag flexo printing machine will be controlled by professional masters from each part to machine forming to test machine, pay attention to the details of each link, in order to make high-quality machines.