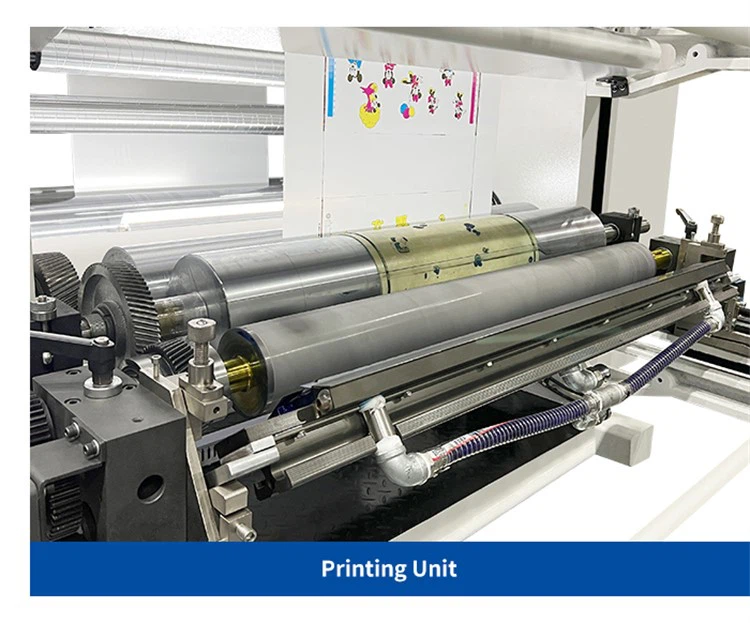

Kraft paper printing machine which utilizes a flexographic letterpress that can be adhered to the printing cylinder. It's basically an updated version of letterpress. It is more versatile than letterpress because it can print on almost any type of substrate, including plastic, film, paper. Widely used for printing non-porous substrates required for various types of food packaging. It is also great for printing large areas of solid color.

- KURUMSAL

- ÜRÜNLER

Plastik Film Ekstrüderleri Yıkama Hatları Yardımcı Ekipmanlar Union Levha Hatları Ekstrüder Kontrol Sistemleri Geri Dönüşüm Makineleri Saldoflex Kesim Makineleri Chovyting Kesim Makineleri Laminasyon Makineleri Geri Dönüşüm Makineleri Dilimleme Makineleri Lab. Ekstrüzyon Hatları Flekso Baskı Makineleri Soğutma Sistemleri Bmtek Kesim Makineleri Plasco Şerit Hatları Gavo Meccanica Masura Kesim ve Birleştirme Makineleri

- TEMSİLCİLİKLER

- TEKNİK DESTEK

- HABERLER

- İLETİŞİM

- MENÜ