Economical CI Printing Machine is versatile and can flexo print various materials such as plastic film, paper, non-woven fabrics, etc. It can greatly reduce labor costs and is one of the first choices for customers to choose flexographic printing machines.

Parameter

|

Model |

CHCI-J (Customizable to fit production and market requirements) |

|||

|

Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

|

Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

|

Max. Machine Speed |

200m/min |

|||

|

Printing Speed |

200m/min |

|||

|

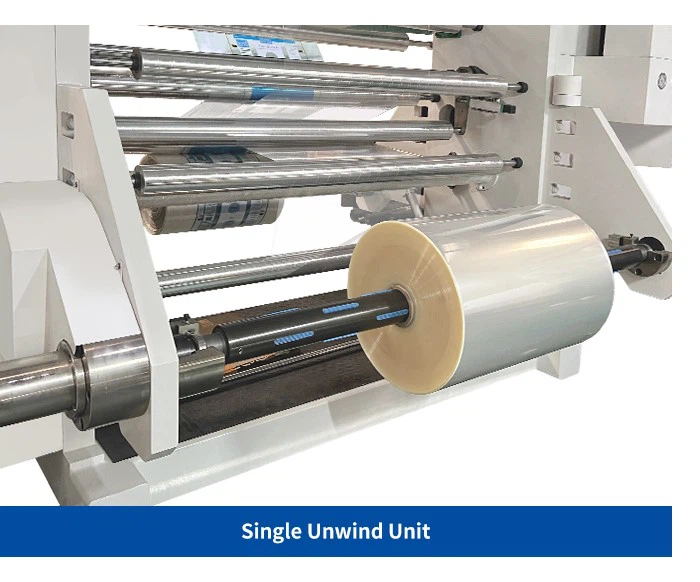

Max. Unwind/Rewind Dia. |

Φ 800mm/Φ1200mm/Φ1500mm |

|||

|

Drive Type |

Gear drive |

|||

|

Plate thickness |

Photopolymer plate 1.7mm or 1.14mm (or to be specified) |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing length (repeat) |

350mm-900mm |

|||

|

Range Of Substrates |

Film,PAPER,NONWOVEN, ALUMINUM FOIL |

|||

|

Electrical supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

Features

1. High-speed printing: These machines can produce prints at a high speed, reducing printing time and increasing productivity.

2. High-volume printing: CI printing machines are designed to handle high-volume printing jobs, making them ideal for commercial printing.

3. Multicolor printing: These machines can print using multiple colors, allowing for high-quality, vibrant prints.

4. Reduced waste: CI printing machines are designed to minimize waste by using precise color registration and ink supply systems.

5. Flexibility: CI printing machines can print on a variety of substrates, including paper, plastic, and non woven.