CI flexo printing machine, several printing units are arranged around the impression cylinder, this kind of printing machine has accurate overprinting and high printing precision, In fact, there is a very big advantage in printing large-area color blocks. Among ci flexo printing machines, 4 color flexo printing machine, 6 color flexo printing machine and 8 color flexo printing machine are more po

Parameter

|

TECHNICAL SPECIFICATIONS |

||||

|

Model |

CHCI6-600E |

CHCI6-800E |

CHCI6-1000E |

CHCI6-1200E |

|

Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

|

Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

|

Max. Machine Speed |

300m/min |

|||

|

Printing Speed |

250m/min |

|||

|

Max. Unwind/Rewind Dia. |

φ800mm |

|||

|

Drive Type |

Gear drive |

|||

|

Plate thickness |

Photopolymer plate 1.7mm or 1.14mm (or to be specified) |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing length (repeat) |

350mm-900mm |

|||

|

Range Of Substrates |

LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon, PAPER, NONWOVEN |

|||

|

Electrical supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

Performance Description

1.Mechanical structure: The printing material is supported by the central large roller, which does not leave the pressing roller between one color and one color. Since the material tape of the Ci flexo printing machine is tightly wrapped on the impression roller, its Constant tension register is very accurate.

2.6 color flexo printing machine whole production line realizes the tension closed-loop speed control mode from the unwinding to the finished product winding, which maximizes the yield of the product.

3.Squeegee device: It adopts two-way closed squeegee, which can print exquisite finished products at high speed.

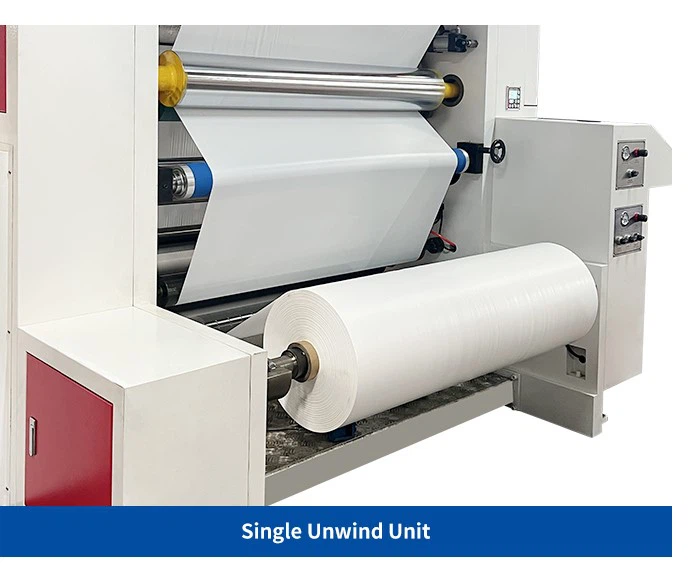

4.Unwinding automatic edge correction: automatic edge correction device is used during unwinding, the tension of the substrate can be stabilized when the machine is stopped.

Features

1. 6 color flexo printing machine Good printing quality and stability, suitable for a variety of printing materials

2. High overprinting accuracy and stability

3. Overprinting and winding are not affected during acceleration and deceleration

4. Less waste of machine adjustment, high printing speed, high output efficiency

5. Relatively simple maintenance and high safety performance

6. The amount of ink applied in flexographic printing is one-third to one-half of that of gravure printing. Satellite flexo printing uses water-based ink printing technology, which is more mature, faster in production, and easy to achieve automatic cleaning.

pular.