Among ci flexo printing machine, stack flexo printing machine and In line flexo printing machine printing, ci flexo press and inline flexo press are the two most important models. Compared with the In line flexo printing machine, the ci flexo printing machine has higher overprinting accuracy. Since the material tape is tightly wrapped on the central impression cylinder, the tension is very stable, and the automatic register control system is not required.

Parameter

|

TECHNICAL SPECIFICATIONS |

||||

|

Model |

CHCI4-600E |

CHCI4-800E |

CHCI4-1000E |

CHCI4-1200E |

|

Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

|

Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

|

Max. Machine Speed |

300m/min |

|||

|

Printing Speed |

250m/min |

|||

|

Max. Unwind/Rewind Dia. |

φ800mm |

|||

|

Drive Type |

Gear drive |

|||

|

Plate thickness |

Photopolymer plate 1.7mm or 1.14mm (or to be specified) |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing length (repeat) |

350mm-900mm |

|||

|

Range Of Substrates |

LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon, PAPER, NONWOVEN |

|||

|

Electrical supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

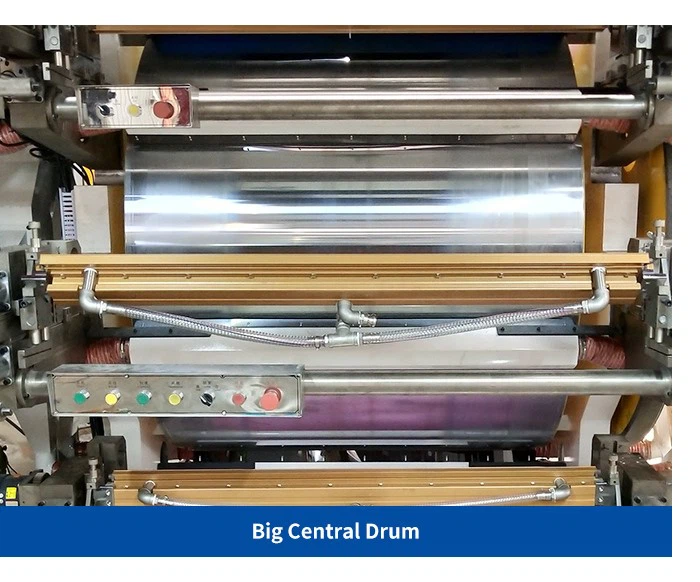

CI Flexo Printing Machine Advantage

(1) Wide range of substrates

The use of flexographic printing machine has low requirements on the flatness of the surface of the substrate, and the printing pressure is light, the substrate is wrapped on a large cylinder, and the tension is very stable. Materials such as Hygiene PE breathable membranes and non -woven fabrics.

(2) Overprinting is accurate

Each printing color group is distributed around the center cylinder, and the printing substrate is closely attached to the surface of the center cylinder, with "zero" tension between each color group, and overprinting is accurate. From unwinding to rewinding, the printing substrate feeding line is very short, with less waste, and the yield of printed products is high.

(3) Consistent ink color and stable quality

Using ceramic anilox rollers to transfer ink, the ink path is short, the amount of ink is uniform, accurate and stable; the ink chamber is sealed to reduce the volatilization of the ink solvent, on the one hand, air pollution is reduced and the working environment is improved; on the other hand, the viscosity of the ink is guaranteed. Accurate control of ink volume and ink color to ensure stable printing quality.

(4) Simple operation and quick order change

Satellite flexo printing machine only needs 1-2 people to easily control the machine, with pre-registration system, pre-adjustment pressure system, order management system, sleeve printing plate roller, anilox roller and closed ink chamber and other devices, Quick order change is possible. In the process of adjusting the machine and proofing, the waste of materials, inks and consumables are relatively small.